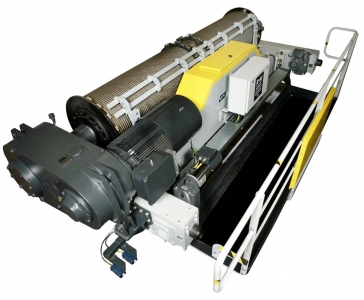

The Spacemaster® SXs’ unique hoist features include new low maintenance, sealed brakes, a two-speed hoist motor, and trolley inverter control. The standard hoist nameplate will carry a CSA c/us rating as well as a NEMA 3R rating for electrical enclosures. Two-component epoxy paint is standard. Spacemaster® SX hoists are designed to meet and exceed either ASME H3 or ASME H4 duty (FEM 1Am, 2m, or 3m) ratings and provide the ultimate in easy load handling, safe operation and lasting, trouble-free performance.

RX PROGRAM – R&M’S REPLACEMENT HOIST FOR EMERGENCY BREAKDOWN SITUATIONS.

- Equipped with standard hoist features

- 230, 460, or 575 volts – 3 phase – 60 Hz power supply